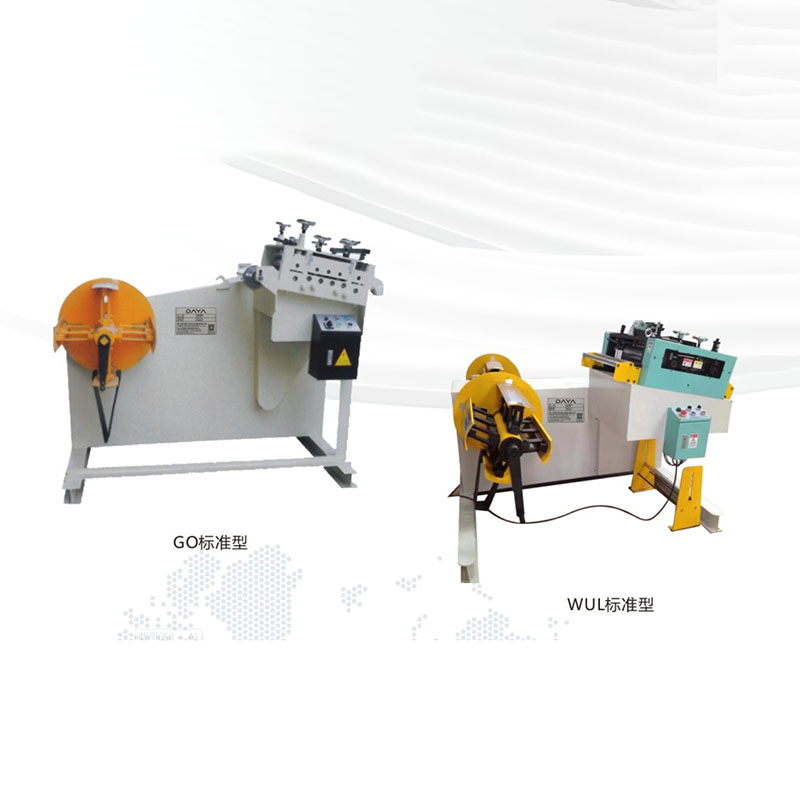

GO, WUL-series Servo Feeder Tshuab

Yam ntxwv

1. Qib hloov haum txais yuav cov khoom siv hluav taws xob digital nyeem 'meter' nyeem ntawv;

2. Qhov siab precision ntsia hlau yog tsav los ntawm qhov zoo thiab qhov tsis zoo ntawm ob txoj kev taug ko taw los tswj kev ntsuas qhov dav;

3. Qhov siab ntawm pub kab noj tau raug kho los ntawm lub zog ntawm lub cev muaj zog;

4. Ib nkawm khoom ntawm lub vov khawm thaiv cov cuab yeej siv rau cov ntawv ntim khoom;

5. Kev pub cov menyuam thiab cov hlau txhim kho tau ua los ntawm high alloy bearing steel (nyuaj chromium plating kho);

6. Hydraulic nias khawm caj npab;

7. Lub iav tsav tsav lub taub hau pub khoom ntawm lub log nias;

8. Hydraulic tsis siv neeg pub mis taub hau ntaus ntawv;

9. Hydraulic txhawb lub taub hau ntaus ntawv;

10. Kev pub noj mov yog tswj los ntawm Mitsubishi PLC program;

11. Qhov raug ntsuas ntawm kev pub mis yog tswj los ntawm Yaskawa servo lub cev muaj zog thiab siab precision planetary servo reducer;

Cov yam ntxwv ntawm ob qho hauv ib qho khoom siv khib nyiab thiab kev siv lub tshuab theem:

1. Cov khoom tso khib tso nrog kev sib xyaw lub tshuab kom ncaj, uas tsis siv qhov chaw. Nws yog qhov yooj yim rau kev khiav lag luam thiab siv cov taub sib txawv ntawm cov khoom siv txhawb nqa kom yooj yim rau kev thauj khoom thiab thau khoom.

2. Nws haum rau txhua yam hlau kauj nrog cov khoom tuab ntawm 0.5-3.0 hli.

3. Nws txais yuav cov hlau tsis sib xws lub cev, uas muaj cov qauv ruaj khov, kev ua haujlwm ruaj khov, kev ua haujlwm me thiab chaw txuag.

4. Lub tshuab raj yog tsim ntawm kev coj tus kheej cov hlau. Tom qab kho cov cua sov thiab ua kom tsis muaj zog ntawm HRC60, nws yog plated nrog nyuaj chromium thiab grinded dua, uas muaj lub zog ruaj khov.

5. Lub tshuab ua kom nres tau tuaj yeem hloov kho kom ua kom lub coil tig nrawm dua thiab ua kom nws lub zog ntsaws.

6. Kev siv lub tshuab hluav taws xob tiv thaiv thiab cov khoom siv hluav taws xob tau siv rau kev tswj hluav taws xob, nrog kev ua txhaum tsawg dua thiab kev pab lub neej ntev.

7. Kev xaiv roj siab tuaj yeem xaiv tau. Vim tias cov khoom siv hnyav, nws tau pom zoo.

Cov khoom siv hluav taws xob, kho tsheb kho vajtse, kho tshuab kho vajtse, khoom siv tiv thaiv huab cua, chav ua noj kho vajtse stamping automation qhib phau ntawv qib haujlwm.

Qhov tsis zoo:

Stamping cov neeg siv khoom siv yog fond ntawm ob hauv ib kablus leveling tshuab. Qhov ob hauv ib qho khoom siv rack thiab qib tshuab ua ke cov khoom sib dhos thiab qib tshuab, uas zoo heev txuag qhov chaw, muaj cov nqi nruab nrab thiab cov nqi tsim nyog, thiab feem ntau yog siv cov khoom siv rau kev teeb tsa ntawm cov kab ntau lawm.

Txoj kev teeb tsa thiab kev debugging:

1. Raws li cov tuab ntawm cov khoom siv raw siv los ntawm cov khoom siv sib txawv thiab qhov ntev ntawm kev pub noj kom nrug, qhov deb ntawm cov khoom noj thiab qhov tuab ntawm cov khoom siv raw yuav tsum txiav txim siab. Yog tias cov khoom siv tuab tuab dua lossis cov kauj ruam pub mis kom ntev dua, qhov kev ncua deb ntawm tus pub yuav tsum tau nce ntxiv, txwv tsis pub, nws tuaj yeem ua kom luv.

2. Lub chaw nruab nrab ntawm cov cuab yeej ncaj yuav tsum tau tuaj yeem nyob hauv kab kev coj ua ntawm qhov chaw pub mis thiab qhov chaw nruab nrab ntawm cov punch tuag.

3. Tom qab txoj haujlwm teeb tsa nyob rau hauv txoj haujlwm zoo, cov ntsia hlau av qis yuav tsum kho kom deb li deb tau kom tiv thaiv kev tawm chaw thaum lub sijhawm cua tom qab.

4. Tom qab kev teeb tsa, thov muab cov roj antirust tso rau hauv lub tshuab thiab rov ntim cov roj lubricating.