80 Nyhav Ib Toos & 110 Tuj C Ncej Tib Qhov Taw Qhia Servo Precision Punch Xovxwm

1 Khoom siv qauv, npe thiab ntau thiab tsawg :

|

Cov khoom siv qauv |

Npe |

Kom muaj nuj nqis |

Lus khaws xav |

| ST-110 |

C ncej ib kis crank precision xovxwm |

1 |

Cov tshuab qog pub rau zaub mov yog tshwj tseg nyob rau ntawm hauv ntej ntawm xovxwm |

2 Lub zog thiab ib puag ncig xav tau

⑴ Lub zog muab hluav taws xob: 380V ± 10%, peb-theem tsib-xaim

Cov cua nrawm: siab 0.6 ~ 0.8mpa

Kev ua haujlwm kub: -10 ℃ ~ 50 ℃

Humidity Ua haujlwm noo: ≤ 85%

3 Cov qauv siv kev tswj hwm

GB / T 10924-2009 《Qhov tseeb ntawm cov ncaj ncaj neeg kho tshuab xovxwm》

GB / T5226.1-2002 《General technical xav tau rau kev lag luam tshuab thiab khoom siv hluav taws xob》

⑶ GB5226.1—2002 《Kev nyab xeeb kev siv tshuab hluav taws xob - ntu I cov txheej txheem kev ua haujlwm》

⑷ JB / T1829—1997 《General kev mob ntawm forging xovxwm》

⑸ GB17120-1997 《Kev nyab xeeb thiab kev ua haujlwm ntawm forging machinery》

⑹ JB / T9964—1999 《Cov cuab yeej xav tau ntawm kev ncaj ncaj lub tshuab xovxwm》

JB / T8609-1997 《Vuam kev mob ntawm forging xovxwm》

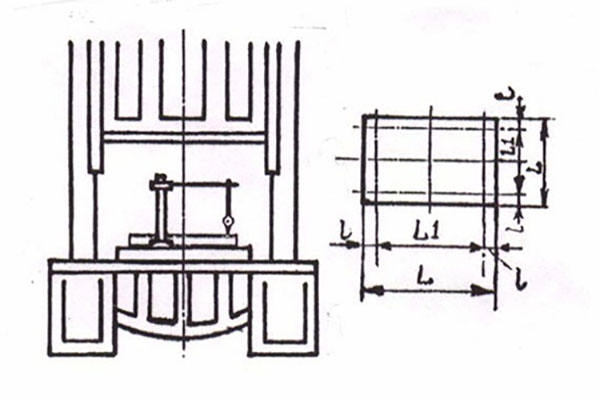

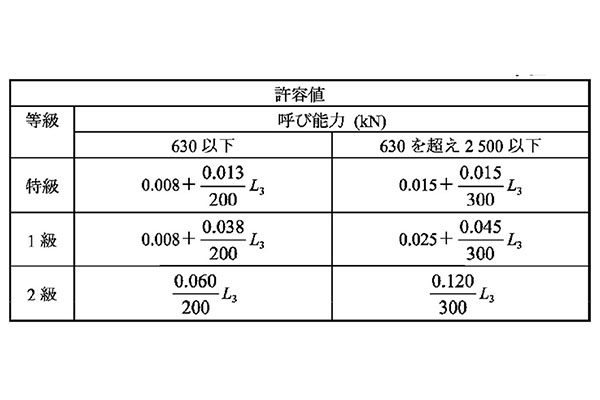

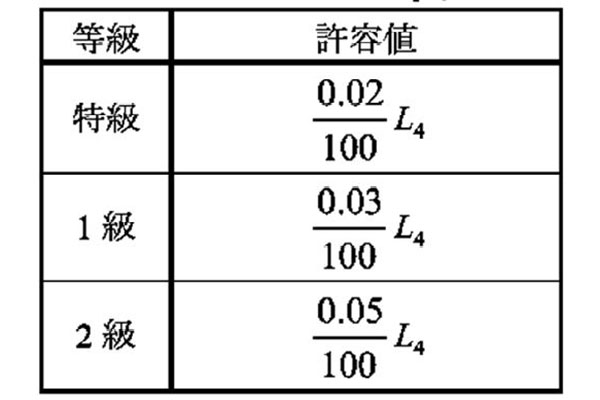

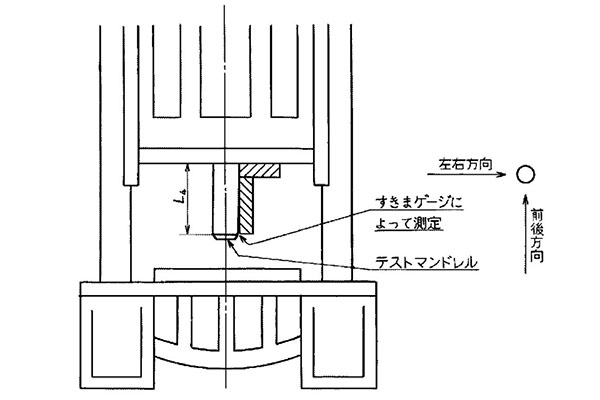

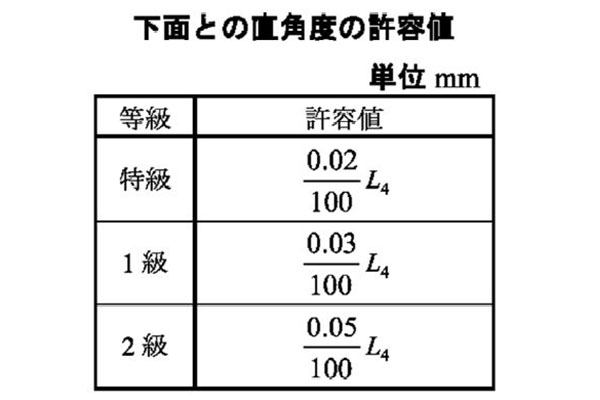

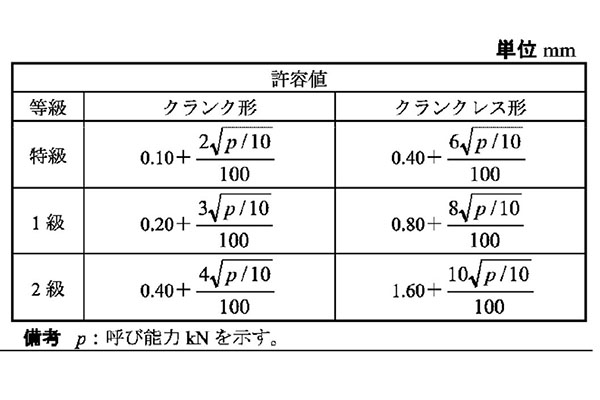

3.1 Cov khoom siv yog raws li Japanese JIS qib 1 precision soj ntsuam txheem:

4 Lub ntsiab ntawm cov khoom siv loj

| Npe |

Chav Nyob |

STA-80 |

STA-110 |

|

| Nominal muaj peev xwm |

TUJ |

80 |

110 |

|

| Muaj peev xwm taw tes |

hli |

3.5 |

4 |

|

|

Zawv zawg ncig ntev |

Plucking Qauv |

hli |

50/90/120 |

60/100/130 |

|

Tas nrho cov lus |

150 |

180 |

||

|

Tsis pub thauj khoom stroke ib feeb ntawm lub nplais |

Sib xws viav hom |

SPM |

120/90/80 |

100/80/70 |

|

Mauv rau mob stroke tag nrho |

~ 70 |

60 |

||

| Qhov siab tshaj plaws modulus qhov siab |

hli |

340 |

360 |

|

| Kev kho me ntsis |

hli |

80 |

80 |

|

| Qhov loj me ntawm kev ua haujlwm sab saud (sab laug thiab sab xis x ua ntej thiab tom qab) |

hli |

770x420x70 |

910x470x80 |

|

| Qhov loj me ntawm kev ua haujlwm qis dua (sab laug thiab sab xis x ua ntej thiab tom qab) |

hli |

1000x550x90 |

1150x600x110 |

|

| Kev sib sib zog nqus qa |

hli |

280 |

305 |

|

| Servo lub cev muaj zog ntswj |

Nm |

3700 |

4500 |

|

| Huab cua qhov chaw siab |

kg / cm² |

6 |

6 |

|

| Precision qib |

theem |

Nyiv JIS qib 1 |

Nyiv JIS qib 1 |

|

5. Kev xav tau kev paub

5.2.1 cov qauv tseem ceeb I

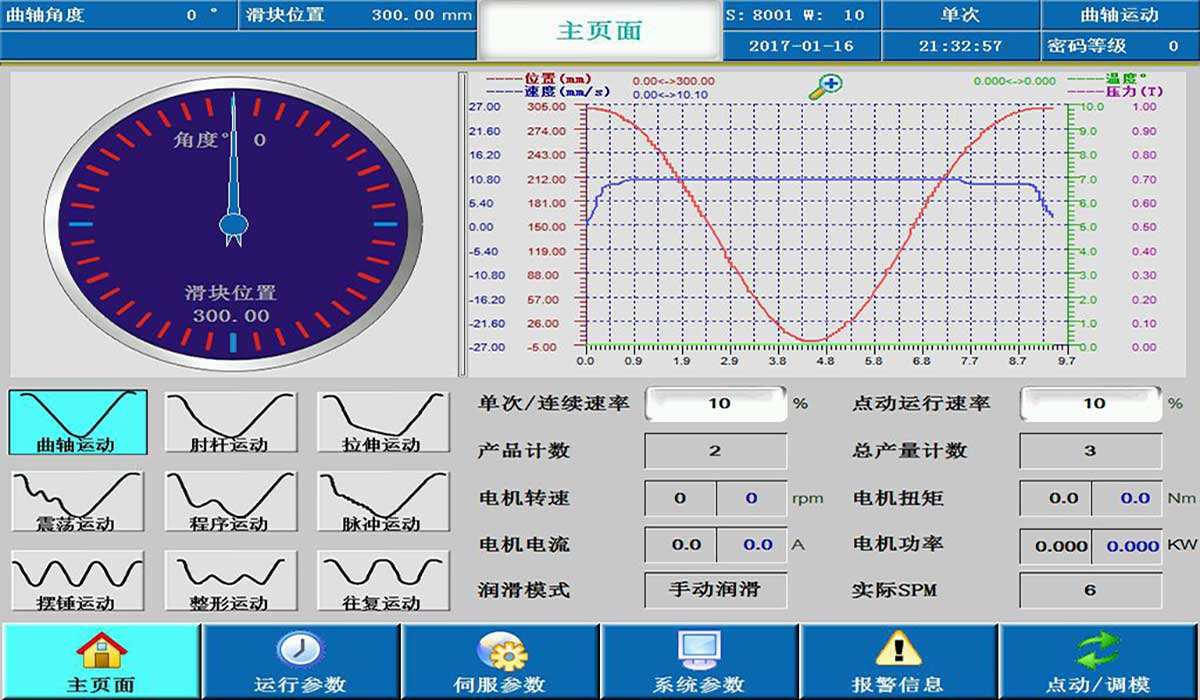

(1) Ua hauv 9 hom kev ua, txhua yam khoom muaj peev xwm xaiv qhov nkhaus uas tsis tsim nyog rau kev ua, Yog li ua tiav high efficiency thiab siab precision.

(2) Piv nrog rau cov punch tsoos, tus qauv yog yooj yim, cov neeg kho tshuab kis tau siab dua, thiab tus nqi saib xyuas qis

(3) Raws li cov yam ntxwv ntawm cov khoom lag luam / cov khoom siv, qhov sib sau nrawm ntawm kev tawm tsam tuaj yeem txo thaum lub sijhawm ua cov khoom, thiaj li ua tiav qhov ua kom zoo ntawm kev ceev ntawm cov khoom / cov khoom. Txhawm rau txo qis kev co, txo lub suab nrov ntawm stamping, txhim kho qhov tseeb ntawm cov khoom thiab ntev lub neej kev pab cuam ntawm lub qhov tuag.

(4) Raws li cov khoom sib txawv thiab qhov siab sib txawv, kev sib tsoo ntawm cov sib tsoo tuaj yeem tsim kev sib cav, uas ua rau lub sijhawm luv luv thiab lub sijhawm ua haujlwm tau yooj yim.

Ua hauv 9 txheej txheem ua qauv

5.2.2 cov qauv nta 2

(1) Kev kub ceev ntau dhau los kho ntawm cov lus qhia swb tsheb nqaj hlau, qhov nyuaj sab saum toj hrc45,

Qhov zoo:zoo heev txhim kho hnav tsis kam. (lwm cov tuam ntxhab tsis muaj kev kho siab ntau quenching)

(2) Qhov kev ua haujlwm saum npoo ntawm qhov khoob thiab cov lus qhia kev tsheb nqaj hlau yog siab li ra0.4-ra0.8,

Qhov zoo:high precision thiab tsis hnav. (tsis muaj quenching thiab sib tsoo kev kho mob los ntawm lwm tus tuam ntxhab)

(3) Lub tiaj tiaj ntawm cov lus qhia qhia kev tsheb nqaj hlau yog 0.01mm / m, thiab qhov npliag yog qhov siab.

Qhov zoo:qhov tseeb tau zoo heev txhim kho. (lwm cov tuam ntxhab saum 0.03mm / m)

(4) Tag nrho peb cov pa hluav taws xob tiv thaiv yog SMC Nyij Pooj. (lwm cov tuam ntxhab feem ntau siv cov khoom lag luam hauv tsev).

(5) Peb txais yuav American MAC hom rau huab cua txau solenoid valve, uas muaj lub siab rhiab heev ntawm huab cua txau cov tshuaj tiv thaiv.

(6) Lub crankshaft ua los ntawm 42crda yog qhov zoo tshaj plaws hauv Suav

Qhov zoo:lub zog yog 30% siab tshaj li ntawm 45 steel, thiab kev pab cuam lub neej ua haujlwm ntev dua. (lwm cov tuam ntxhab feem ntau siv 45 steel)

(7) Lub tes tsho tooj liab yog ua los ntawm zqsn10-1 (Tin Phosphorus Bronze) (zoo ib yam li Aida tooj liab lub tes tsho). Lwm cov chaw tsim khoom tsim bc6 (siab lub zog tooj dag, tseem hu ua 663 tooj liab), muaj 50% siab dua lub zog (lub zog siab) dua li cov tooj liab zoo nkauj, thiab yog hnav ntau dua thiab tiv taus, Ntev ntev dua thiab kev pab lub neej ntev dua.

(8) Tag nrho peb cov kav dej yog Φ 6, thiab cov roj hluav taws xob kom du thiab tsis yooj yim rau kev thaiv. (lwm cov tuam ntxhab feem ntau siv Φ 4)

(9) Lub rooj zaum pob adopts Japanese TM-3 sintered tooj liab (tib yam li Aida)

Qhov zoo: qhov tshwm sim ntawm kev tom yog txo tsawg (cov tuam ntxhab feem ntau yog cam khwb cia hlau).

Muaj kev cuam tshuam ib puag ncig

Cov khoom no tsis muaj kev cuam tshuam rau ib puag ncig thiab yuav tsis tsim cov khoom tsim kev phom sij.

Kev nqa thiab teeb tsa

⑴ Thauj khoom thiab ntim khoom ntawm cov khoom:

Cov cuab yeej siv cov kev tsim nyog los tiv thaiv xeb, tiv thaiv kev co thiab tiv thaiv kev cuam tshuam hauv cov txheej txheem ntim, uas tuaj yeem lav qhov kev thauj mus los thiab khaws cia 5 ° c ~ 45 ° c.

Thaum cov khoom siv thauj mus los thiab khaws cia, yuav tsum them nyiaj rau nws. Cov khoom siv thiab ntim khoom sab nraud yuav tsum tsis txhob nphav los nag lossis dej, thiab lub ntim sab nraud yuav tsum tsis txhob puas.

⑵ Nqa cov khoom siv:

Thaum nqa thiab tsis thauj khoom los ntawm crane, hauv qab lossis ib sab ntawm cov khoom yuav tsum tsis muaj kev poob siab lossis lub zog kev co.

Lub installation:

Tshem tawm thiab ntxuav cov yas txheej qhwv ntawm sab nraum, tshem tawm lub ntsaws, thiab nruab PU1 yeeb nkab txuas thiab PU yeeb nkab, qhov ntev ntawm cov yeeb nkab PU yog li 700 hli.

5.2 Lub ntsiab tivthaiv cov qauv

. Cuab Yeej seem

Cov thav duab tau txuas nrog cov khoom Q235B. Tom qab welding, tempering yog nqa tawm los tshem tawm qhov kev ntxhov siab sab hauv ntawm cov khoom. Fuselage qhia kev tsheb nqaj hlau txoj hauj lwm nrog ob lub kaum ntsej muag ntawm rau txoj kev tsheb ciav hlau.

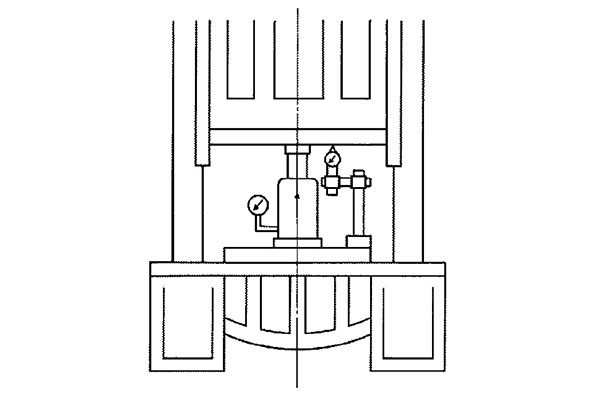

Type Hom sib kis

Cov kis xaib, crankshaft thiab cov pas nrig sib txuas yog sib sau ua ke nyob rau sab qaum kev xovxwm. Lub cev muaj zog yog ntsia ntawm lub ntsuas qaum qhov ntsuas ntawm tus ncej, flywheel, clutch, thiab lwm yam

Hauv qhov chaw ntawm lub nraub qaum ntawm thav duab, flywheel tau sim rau kev tshuav nyiaj ua ntej sib dhos.

Lub iav tshooj adopts ncaj hniav kis mechanism, thiab nws cov khoom siv yog ua los ntawm lub zog loj lub zog hlau 42CrMo, thiab coj tau cov kev kho cua sov yog nqa tawm.

Qhuav qis inertia clutch / nres. Clutch / nres lub kaw lus tswj hwm tau nruab nrog lub tshuab kuaj xyuas lub tshuab qias neeg.

Tag nrho cov shafts tau txais yog ua los ntawm tin-phosphorous bronze hnav-resistant khoom.

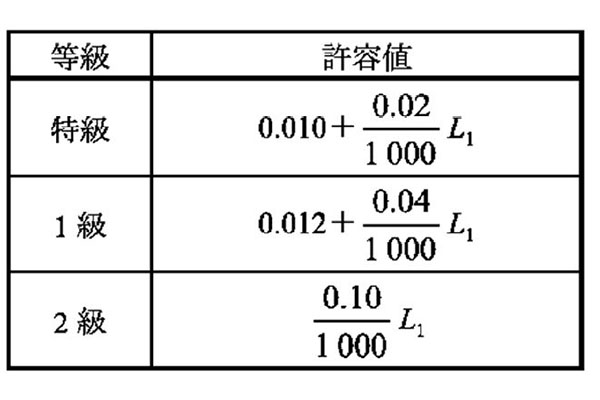

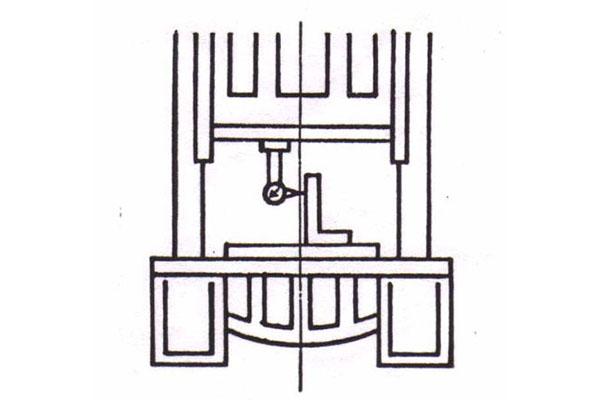

Lub vaub txav

Cov nplais ntawv yog ua los ntawm HT250 cov khoom. Cov lus qhia adopts ob-point rau-sab kev qhia,

Hauv qab npoo ntawm swb swb thiab thaj tsam sab saum toj ntawm lub rooj muaj T-groove, uas yog siv los nruab cov pwm. Qhov siab ntawm cov swb zawv zawg tau muab kho los ntawm lub zog hluav taws xob ntau dua 80 tons (suav nrog).

Txais yuav hydraulic tsis siv neeg tshaj kev tiv thaiv kev tiv thaiv.

SystemLubrication system

Cov xov yog lubricated nrog hluav taws xob butter thiab nruab nrog qis roj theem ceeb toom lub cev, yog li nws muaj kev nyab xeeb thiab txhim khu kev qha. Lub vaj huam sib luag yog: phau ntawv qhia butter noj mis.

Kev ntsuas lub kaw lus kom sib npaug

Txais yuav los ntawm huab cua siab hom swb thaiv qhov ntsuas tshuav qhov sib npaug, Cov cua nrawm tuaj yeem tswj tau los ntawm huab cua siab tswj qhov ntsuas.

⑹ Hluav Taws Xob

Cov khoom siv hluav taws xob yog tswj los ntawm PLC, nruab nrog muaj zog ntawm tib neeg-tshuab cav, thiab tso tawm los ntawm qhov kov kov ntawm cov npe nrov.

Muab tso rau ntawm lub lag luam tseem ceeb, cov haujlwm hauv qab no tuaj yeem ua tiav:

Touch Cov ntsuas phoo kov tau qhia txog cov cim hauv Suav (lossis hloov ntawm Suav thiab Askiv), uas yog yooj yim thiab to taub yooj yim, thiab qhia ntau yam ntaub ntawv ntawm cov xovxwm, xws li cov xov tooj ntawm cov cwj nrag, cov hluav taws xob hauv CAM CAM, thiab lwm yam ntaub ntawv sib xws tau tau teeb tsa los ntawm qhov kov lub npo;

Tshaj tawm cov haujlwm ua haujlwm ntawm cov xovxwm, kom tus neeg teb xov tooj tuaj yeem ua haujlwm xovxwm tau yooj yim dua,thiab muaj qhov qhia tau txaus rau lub xeev ;

③ Kev ua haujlwm thiab ua tsis tiav cov ntaub ntawv tso tawm, kom cov neeg ua haujlwm thiab cov tswj xyuas kom nrawm dua los daws cov teeb meem xovxwm, txo lub sijhawm qis qis;

PLC cov tswv yim / cov khoom tso tawm taw qhia lub sijhawm ua haujlwm xyuas tiag tiag;

⑤ Teem cov khoom lag luam tshuaj ntsuam, uas tuaj yeem ua kom pom cov khoom lag luam tam sim no nyob rau lub sijhawm tiag tiag, thiab teeb tsa cov phiaj naj npawb ntawm cov khoom ua haujlwm.

Kev tswj hluav taws xob xovxwm adopts peb-theem fais fab mov, 380V, 50Hz.

Lub cev muaj zog yog nruab nrog thermal overload thiab xoom nrawm tiv thaiv kev tiv thaiv.

Qhov paub tseeb ntawm txhua txoj haujlwm ntawm kev tswj hwm punch muaj cov hlua txuas rau kev nyab xeeb. Lub vaj huam sib luag yog nruab nrog qhov taw qhia txhaum lub teeb thiab rov khawm pib ua kom tiav txoj haujlwm ntawm kev rov ua dua tom qab kev ua txhaum kev paub.

5.3 Hom kev khiav haujlwm

Xovxwm teeb inching, ib, txuas ntxiv mus peb hom kev ua haujlwm. Tus txheej txheem ua haujlwm yog xaiv los ntawm tus hloov thiab tswj hwm ntawm lub pob.

5.4 Kev ntsuas kev nyab xeeb

Button Lub pob tshuaj thaum muaj xwm ceev: nias lub pob "thaum nres xwm ceev" thaum muaj kev ua haujlwm tsis zoo ntawm xovxwm. Cov xovxwm muaj peb lub khawm xwm ceev.

Ib qho ntawm lub lag luam tswj lub vaj huam sib luag, ib qho ntawm kab, ib qho ntawm ob lub cev haujlwm ua haujlwm; Nias ib yam ntawm cov khawm ti tes ti taw thiab xovxwm yuav nres tam sim ntawd. Txoj haujlwm ntawm lub khawm nres ceev ntawm kem yog kwv yees li 1.2 metres ntawm qhov av, uas ua tau raws li qhov yuav tsum tau ua ntawm ergonomics;

⑵ Lub sijhawm ua haujlwm ob txhais tes: ob txhais tes nqes rov qab lub sijhawm ua tiav yog 0.2-0.5s;

Tshaj dhau kev tiv thaiv: lub swb thaiv yog nruab nrog hydraulic overload tiv thaiv kom paub tseeb tias xovxwm yuav tsis puas xovxwm thiab tuag vim yog dhau.

Tshaj dhau tom qab tus swb uas nyob qis dua ntawm qhov chaw tuag, tsuas yog siv inching, rov qab mus rau sab saum toj kawg nkaus tuag rau kev rov ua dua thiab siab, ua haujlwm.

6. Kev teeb tsa ntawm cov khoom siv

6.1 Lub ntsiab qauv ntawm ntu

|

Txog ntawm tus lej |

Feem Lub Npe |

qauv |

Cov ntaub ntawv, cov qauv kho |

|

1 |

Lub tshuab thav duab |

Qhov yooj yim |

Cov Ntaub Ntawv Q235B |

|

2 |

Ntshoo |

Qhov yooj yim |

Cov Ntaub Ntawv Q235B |

|

3 |

Crankshaft |

Qhov yooj yim |

Cov Khoom Siv 42CrMo, quenched thiab tempered Hs42 ± 20 |

|

4 |

txawj ya |

Qhov yooj yim |

Cov Khoom Siv HT-250 |

|

5 |

Hauv yias |

Qhov yooj yim |

Cov Khoom Siv HT-250 |

|

6 |

Lub tog raj kheej |

Qhov yooj yim |

Cov ntaub ntawv 45 |

|

7 |

Cov cab iav |

Qhov yooj yim |

Cov Khoom Siv ZQSn10-1 Tin phosphor tooj |

|

8 |

Nawb |

Qhov yooj yim |

Cov ntaub ntawv 40Cr, quenched thiab tempered Hs40 ± 20 |

|

9 |

txuas |

Qhov yooj yim |

Cov khoom siv QT-500 Kev kho tsis meej |

|

10 |

Sawtooth pob taub hau |

Qhov yooj yim |

Cov ntaub ntawv 40Cr, quenched thiab tempered Hs40 ± 20 |

|

11 |

Daim phiaj xwm qhia qeeb |

Qhov yooj yim |

Cov Khoom Siv HT-250, Kev ua haujlwm siab quenching hrc45 qib siab dua |

|

12 |

Tooj liab (lub tes tsho tooj liab) |

Qhov yooj yim |

Cov Khoom Siv ZQSn10-1 Tin phosphor tooj |

6.2 Main feem chaw tsim tshuaj paus / hom

|

Nunber |

Feem Lub Npe |

Chaw tsim tshuaj paus / hom |

|

1 |

Main servo lub cev muaj zog |

Dengqi |

|

2 |

Lub tsheb kauj vab hloov kho lub tsheb |

SANMEN |

|

3 |

PLC |

Nyiv Omron |

|

4 |

AC contactor |

Fabkis Schneider |

|

5 |

Nruab nrab relay |

Nyiv Omron |

|

6 |

Clutch qhuav nres |

Ltalis OMPI |

|

7 |

Ob chav solenoid valve |

TEB CHAWS USA ROSS |

|

8 |

Thermal relay, ntu txuas |

Fabkis Schneider |

|

9 |

tswj khawm |

Fabkis Schneider |

|

10 |

Huab cua pom |

Nyiv SMC |

|

11 |

Roj mister |

Nyiv SMC |

|

12 |

Siab txo lub valve |

Nyiv SMC |

|

13 |

Hydraulic ntau tshaj twj tso kua mis |

Nyiv , Showa |

|

14 |

Lub ob txhais tes khawm |

Nyiv Fuji |

|

15 |

Roj fais tshuab tso kua mis |

Nyiv IHI |

|

16 |

Cov kabmob tseem ceeb |

USA Timken / TWB |

|

17 |

Los tiv thaiv kev co ko taw |

Hengrun |

|

18 |

cua hloov |

Fabkis Schneider |

|

19 |

Zaus hloov dua siab tshiab |

ZHENGXIAN |

|

20 |

kov npo |

Kunlun Tongtai |

|

21 |

Ntsaws ruaj ruaj |

Taiwan SOG |

|

22 |

Cov tshuaj tiv thaiv ua ntej |

Nyiv Omron |

|

23 |

Ntau seem hloov |

Siemens, Lub Tebchaws Yelemees |

|

24 |

Cua tshuab ntaus |

USA MAC |

|

25 |

Pwm tuag illumination |

Puju LED |

|

26 |

Misfeed nrhiav kom tau interface tshwj tseg |

Thaiv los ntawm PLC |

|

27 |

Photoelectric tiv thaiv ntaus ntawv |

LAIEN |

6.3 Khoom siv, cov cuab yeej tshwj xeeb sau npe

|

Yam Lub Npe |

Hom khoom thauj |

Kom muaj nuj nqis |

Yeem / tus qauv |

|

Txij nkawm twj thiab cov cuab yeej |

khoom siv |

1 teeb |

txuj |

6.4 Cov khoom siv tshwj xeeb (rau kev xaiv) npe

|

Tooj |

lub npe |

Lub Hom |

Yeem / tus qauv |

|

1 |

2-channel tonnage |

Nyiv Rikenji |

Yeem |

|

2 |

Cov ntsuas nrhiav tsis zoo |

Nyiv Rikenji |

Yeem |

|

3 |

Hauv qab taw tes tuag taw kuaj nrhiav khoom |

Nyiv Rikenji |

Yeem |

|

4 |

Kev hloov pwm sai hloov ntaus ntawv |

Taiwan Fuwei |

Yeem |

|

5 |

Feeder tshuab |

Taiwan TUOCHENG |

Yeem |

|

6 |

Tuag ncoo (cua cushion) |

tus kheej tau ua |

Yeem |

|

7 |

Cov pab pawg pub |

tus kheej tau ua |

Yeem |